Andrew Howell (1986) is Executive Vice President of Technology at KBC Advanced Technologies. He has had a long and successful career in the oil and gas industry and now works to promote decarbonisation and sustainability in the sector. In this article he talks about the importance and challenges of the transition to greener fuels.

Career history

I graduated with two years of Engineering and two years of Chemical Engineering in the summer of 1990. I had always been a mathematician with an interest in chemistry and physics and a bit of an aversion to biology, so Engineering seemed like a good place to be. A fascination in fast (I am a motorcyclist at heart!) and large machines pushed me to large-scale engineering projects such as offshore oil platforms.

During the ‘Milk Round’ I discovered that oil companies in 1989-90 were a good place to be for salary, international travel and experience. I have since lived in Aberdeen, Los Angeles CA, Calgary (Canada), Houston TX, Perth (Australia) and London UK.

In 1987, while I was studying Engineering at Cambridge, the Piper Alpha disaster in the Offshore UK Sector of the North Sea claimed 167 lives. I wanted to be part of a generation of engineers that could deliver these highly challenging engineering projects more safely, reliably and sustainably. BP offered me a graduate position and my career in oil began.

Over the last 33 years I have worked in Upstream Oil and Gas Production, Oil Refining and Petrochemicals for a number of companies. These form different parts of the hydrocarbon sector but are bound together by a common supply chain and are often co-located with similar challenges. The biggest challenge they share today is decarbonisation.

I have always been focused on safety, reliability, optimisation and efficiency in our industry. These are all building blocks of sustainability and I am finding a renaissance in my industry and my own career in this area.

The energy transition to greener fuels

To understand where we are going we must acknowledge where we have come from. The modern oil era began in 1859 in Titusville, Pennsylvania where the first oil well was drilled. This, combined with coal, meant that hydrocarbons began to drive improvements in living standards 20-fold in the past 200 years compared to less than 3-fold improvement in the 800 years before.

Hydrocarbons provide a ‘cheap’ and usable form of transport fuels and feedstocks for carbon materials that have revolutionised our world. The key thing for transport is that the energy source needs to be mobile with a high concentration of power, which we call calorific value. I believe that, outside of nuclear sources, you cannot beat the energy power contained in gasoline, jet fuel or diesel, and it’s relatively easy to contain, transport and burn.

Another factor is that the most efficient processes are when the energy is generated close to where it is consumed, and losses in between are minimised. You can’t get much more efficient than the internal combustion engine where the combustion cylinders are only inches from the gear box. And so the internal combustion engine has ruled for over 100 years!

However, the increasing carbon dioxide emissions from extracting, producing and using hydrocarbons have led to the current climate crisis. The time for change is upon us, but that change must be an evolution that maintains our living standards.

Cleaner energy

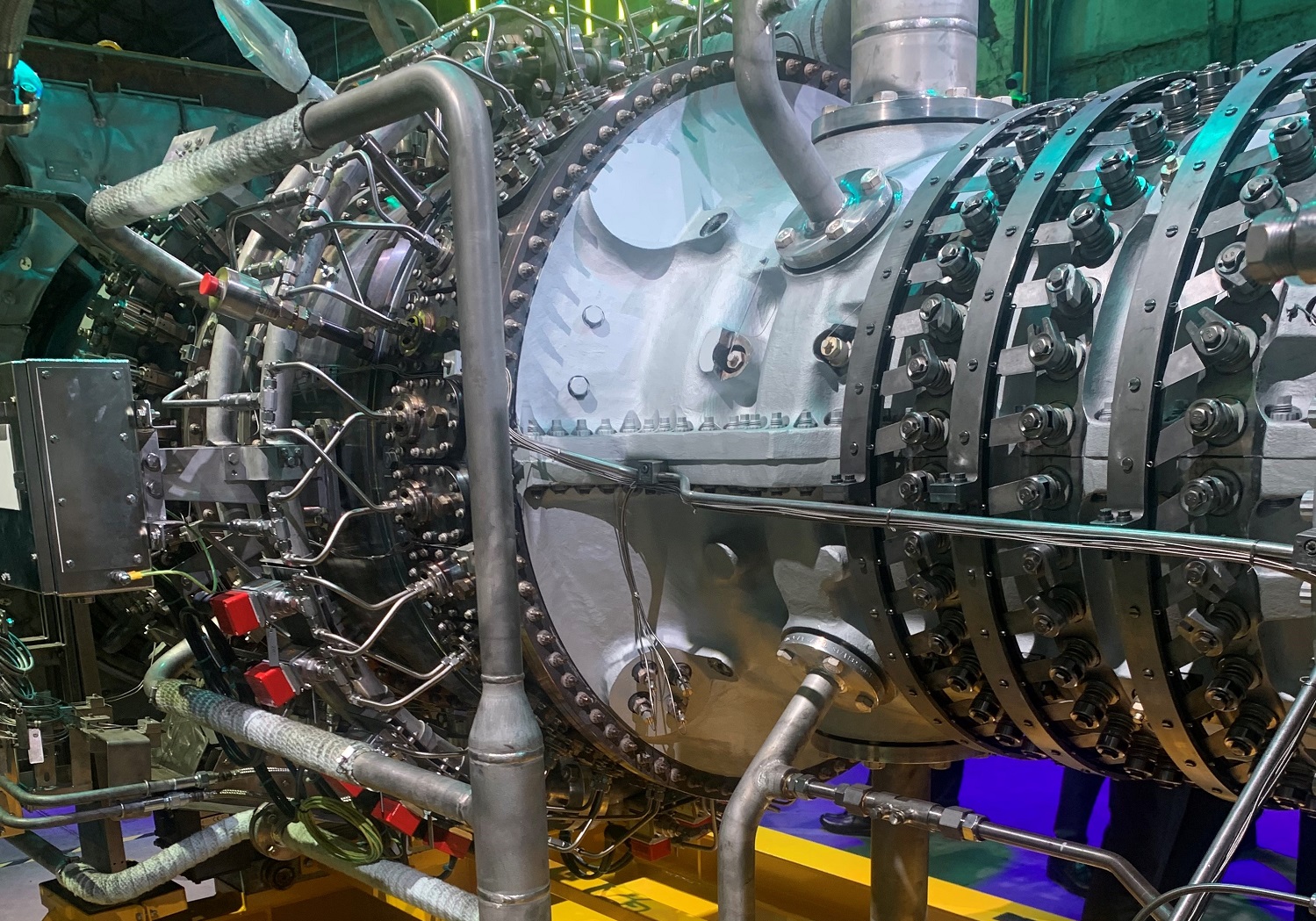

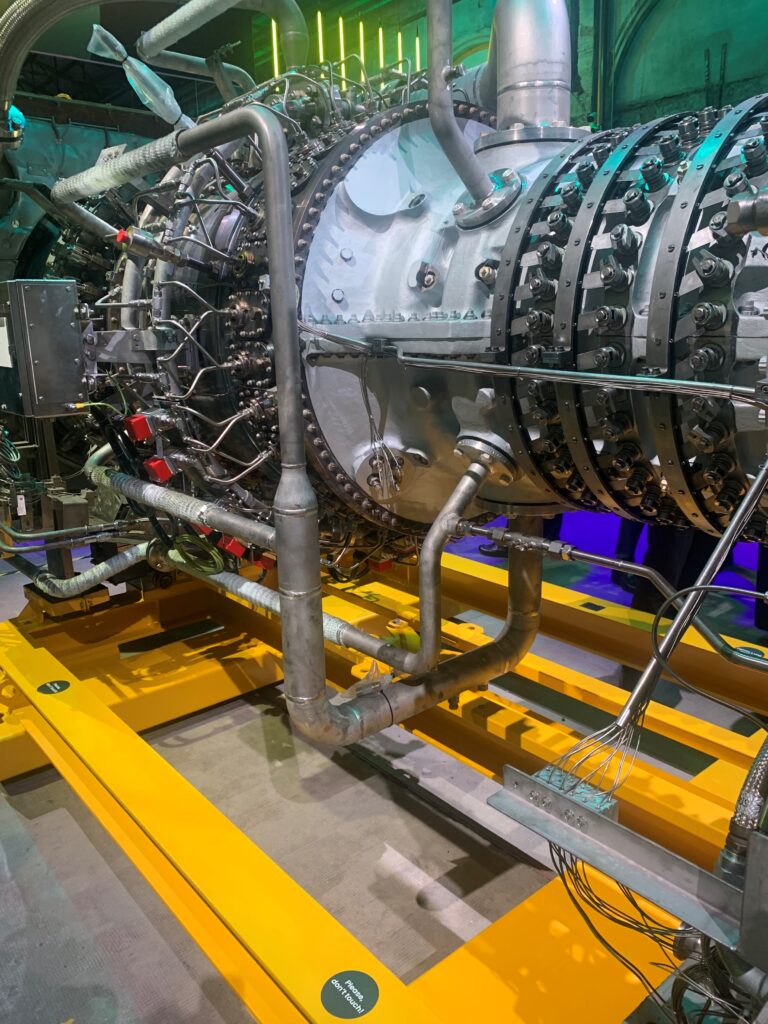

Within the hydrocarbon sectors there are steps that can be taken towards cleaner fuels, for example oil is better than coal, but natural gas is better still. Natural gas combined-cycle power plants can emit less than 60% of the carbon dioxide of a coal plant for the same electricity generation, especially when the heat is recovered from the exhaust gasses in a steam generator. My own fascination with machines has led my career to the specification and operation of these gas turbines.

Current role

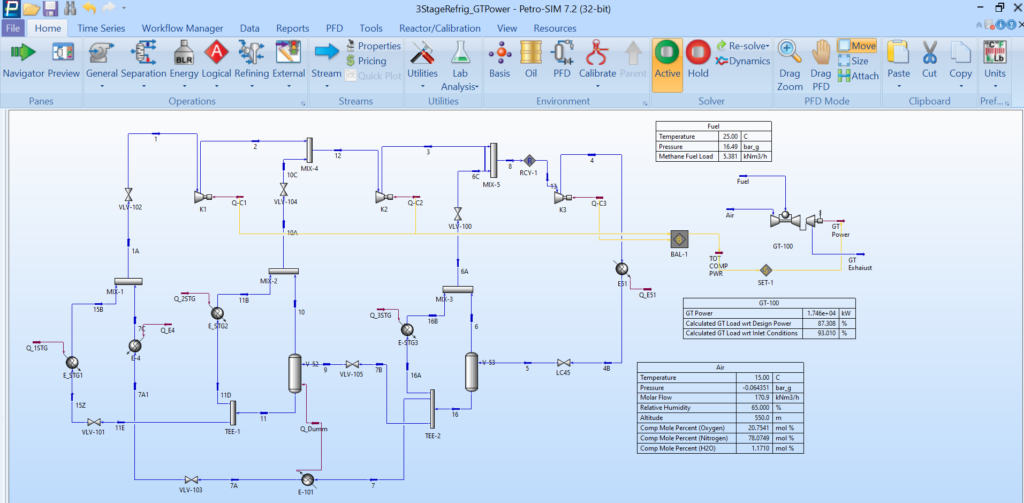

Today I am the EVP of Technology (software) at KBC Advanced Technologies, a UK engineering firm which is part of a Japanese company called Yokogawa Electric. We focus on the simulation and improvement of hydrocarbon processes to drive energy efficiency and decarbonisation. We specialise in process simulation models that can act as a digital twin model of the asset and be used offline and online to drive improvements in hydrocarbon processing as per below:

My typical day involves working with customers to plan for simulation models to improve energy efficiency or test decarbonisation solutions, and working with my global team of sales, support engineers, implementation engineers and R&D programmers to ensure we are offering value to our clients.

The oil company energy transition challenge

Hydrocarbon operations must become ‘energy complexes’ with an actionable plan to eliminate fugitive emissions, decrease carbon footprints in day-to-day activities, substitute products for lower carbon versions and, ultimately, replace carbon in favour of other molecules such as hydrogen, oxygen and nitrogen.

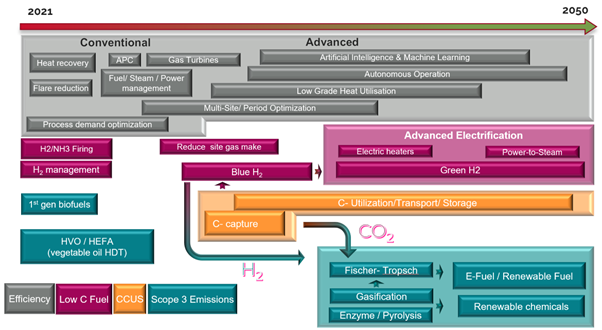

The best practice is to reflect on the big picture, identify what reductions can be made today and then over 10-20 years of operation, and construct a strategic roadmap that converts strategy into action. These reductions are grouped into Scopes 1, 2 and 3 as defined by the United Nations. Scope 1 is to reduce emissions in your processes; Scope 2 is to avoid buying in energy from another source rich in emissions; Scope 3 is to reduce the resulting emissions from the use of products by customers.

The public perception is of the oil industry and governments painting a good picture but not delivering, termed ‘green washing’. There is no room for that in our company. Engineers have created the climate challenge, but they can also solve it. The following graphic shows examples that we have simulated and developed for options in Scope 1-3 emissions reduction.

These include using less energy intensive recycled carbon sources for fuel, for example cooking oil or bio-fuels derived from crops, and creating hydrogen from water electrolysis powered by green energy.

I am proud to be a chemical engineer involved in making the energy transition happen. My biggest ambition is to stop taking polystyrene to the local dump and to see it recycled to make styrene monomer for re-use in a net zero circular process.

I would encourage everyone to think twice about throwing away plastic – we can recycle it to lower-carbon gasoline these days!